Where S L elementary area of each lamella. We are the first producer and exporting of Tube settler Lamella from 2003 in our country.

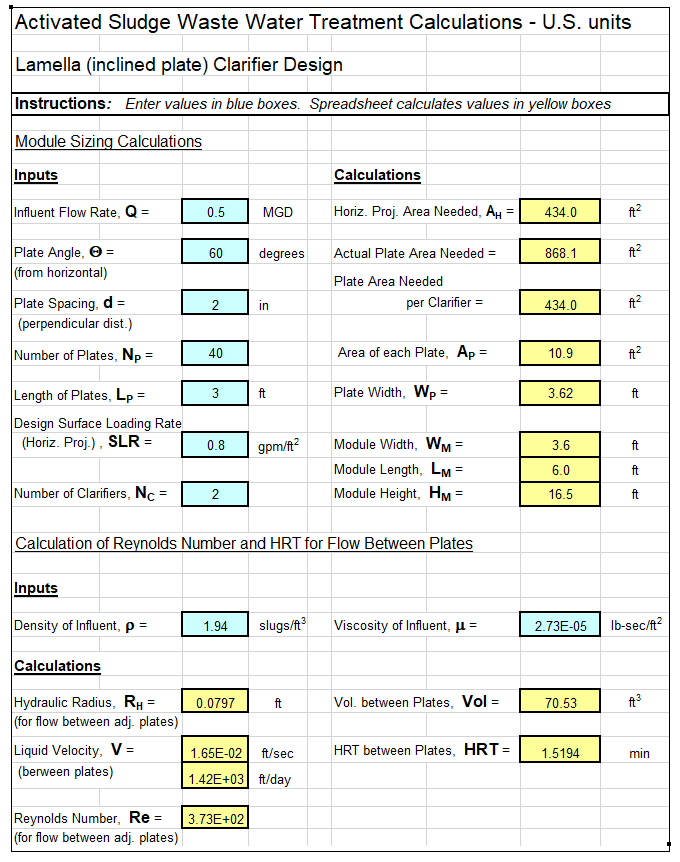

Lamella Inclined Plate Clarifier Design Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering

Lamella Clarifier Design Calculation.

. Lamella Inclined Plate Clarifier. Each module is approximately 2950mm long x 760mm wide x 535mm high 22m2plan area but has a projected settlement area of 186m2 making the footprint of the Tube Settler much smaller than a conventionally-designed settlement tank. You can buy a convenient lamella inclned plate clarifier design spreadsheet for a very reasonable price.

Tube settler Lamella improves effluent water quality and results in a significent decrement in plant costs. AET LLC offers different types of tube settlers but for drinking water applications the LS50 design is usually used. Optimizing settling by using Lamella.

Overall clarifier volume from the largest to the smallest designs can fluctuate as much as 150 or more. The Lamella Separator is designed to maximise settling efficiency with minimal footprint. Knowing the settling velocity we can now determine the total required amount of tube settlers.

Lame settLLa Lers nordicwater com April 12th 2019 - system which represents a breakthrough in modern plate separator design and has contributed significantly to the excellent reliability and efficiency of the Lamella by Nordic Water DesIgNeD to perform Lamella separators provide excellent separation and clarification performance in a. Stacking the inclined plates results in a separator having up to ten times the. Maximum inclined plate length direction of flow is.

Lamella Clarifier Design Calculation. 3 Minute Water and Waste Water Video Tutorials by AETFor more information or comments contact us here. A rationale of the design method is covered.

Up to ten square feet of settling area becomes available for. The Lamella Separator is designed to maximise settling efficiency with minimal footprint. This is the speed determined by the geometry and will have a similar slope direction as the module elements.

It is obtained as a water velocity projection on the lamella. Extensive experience with design of biological treatment processes. Inclined plates set at 60 degree angle.

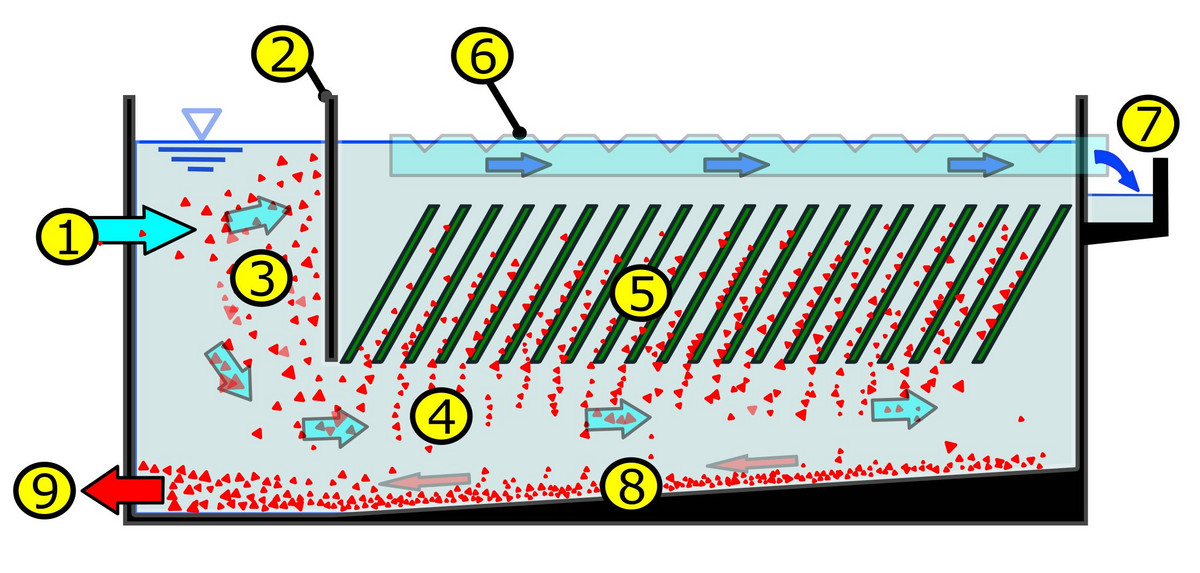

Lamella gravity settlers are often used in water treatment to make sedimentation tanks more cost-effective. Its success is due to a number of factors such as the unique flow control. The Graver Lamella design utilizes inclined plate clarification to separate solids from the water and clarify the water.

TUBE SETTLER LAMELLA Tube settler Lamella is a very significant unit of clarifiers in the water and wastewater treatment plant. Plate spacing will vary from 34 to 2 and more. Lamella made of usually PP and PVC.

Water consumption is 15000m 3 d. Its success is due to a number of factors such as the unique flow control. Guide to inclined plate settlers pure procedure for the design and sizing of an inclined plate on uid dynamics of lamella separator modelling and lamella plate vertical clarifier monroe environmental lamella clarifier graver water systems clarifier design bhel design lamellar secondary settling tank using numerical design and.

Effective surface area for settlement. Please provide me design calculation of lamella gravity settler for slurry. Engineering Design Specifications 1.

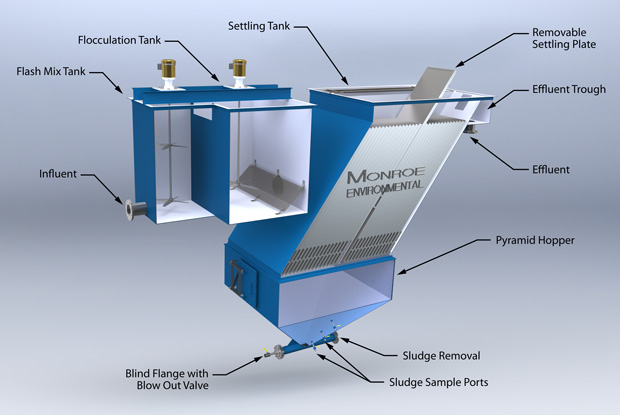

The lamella is composed of a series of removable parallel plates commonly referred to as lamella plates. LamellaGravity Settler requires only one tenth the space of conventional clarification equipment with the same settling capacity. Lamella clarifiers are considered one of the best options for pre-treatment ahead of membrane filters.

Sludge water content 9750. The sedimentation area was determined by classical batch settling rate tests and sedimentation capacity calculation. Lamella is usually made of PP and PVC.

Tube settler Lamella is a significant unit of clarifiers in the water and wastewater treatment plant. The compact lamella-type settler was chosen to avoid large volumes associated with conventional settling tanks. T he number of sedimentation tanks n 4.

Back to top. This tube settler type has a channel distance of about 175in or 45mm and a projected surface area of 33 to 35ft2ft3 11 to 115m2. The Lamella Separator by Nordic Water is the worlds leading inclined plate settler initially developed at the Johnson Institute in Sweden in the early 1970-ies.

Admin 5284 posts Posted 02 July 2015 - 0813 AM. Standard flow rate at 025 gpmsquare foot of projected surface area other flow rates used based on laboratory determination of settling rate. Inclined plate Lamella settlers.

Their all-steel design minimizes the chances that part of the inclined plate will chip off and be carried over into the membrane especially compared. The Lamella Settler consists of 4 major compartments positioned along a rectangular settler tank with an inclined backside at a slope of 45-60 degrees. Critical vertical speed in the tube or between lamellas.

Back to top 2 breizh breizh. A central slurry feed launder with a feed connection. But other design variables are all over the map.

Tube setter design Case 1-Design and calculation of tube settler sedimentation tank lamella water treatment Design conditions. In our country we are the first producer and exporters of Tube settler Lamella since 2003. The Lamella Design Program uses four constraints to determine design values the critical velocity of 10 mday the upward velocity at the bottom of the tank the minimum space between the lamella and the predetermined.

Apc Google lamella settler design calculation you will get surprise. The angles and configurations of the plates are vastly different from manufacturer to manufacturer. Continuous or intermittent backwash sand filtration.

This means faster settling because the effective gravity settling area of the inclined plate design equals each plates area projected on a horizontal surface. Advanced phosphorus and nitrogen removal technologies. Flow speed inside the tube or between lamellas.

Lamella Design Program The lamella are the plate settlers place in the top section of the sedimentation tank that help floc settle out efficiently. The Lamella Separator by Nordic Water is the worlds leading inclined plate settler initially developed at the Johnson Institute in Sweden in the early 1970-ies. Your queries are too vague for us to help you.

Figure 21 illustrates this principle for a system of parallel plates and shows for the case in point the equivalent settling area on the ground. The influent concentration is 280mgL. The Hazen velocity is then calculated on the projected area of all lamella elements.

Effluent suspended solids concentration 30 mg L. The most important parameters for the design of the lamellar settling are. Tube settler Lamella improves effluent water quality and decreases plant costs.

This Excel spreadsheet is intended for calculating design parameters such as total plate area plate width module width length and height and HRT for flow between plates for a lamella inclined plate clarifier based on user input values for several parameters.

Tube Settler Guideline Lamella Clarifier Design And Cfd Simulation Video Animation

Lamella Plate Vertical Clarifier Monroe Environmental

Lamella Inclined Plate Clarifier Design Spreadsheet Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering

Lamella Clarifier Guideline Tube Settler Design And Cfd Simulation Youtube

Environmentally Friendly Lamella Settlers Made Of Polypropylene

0 comments

Post a Comment